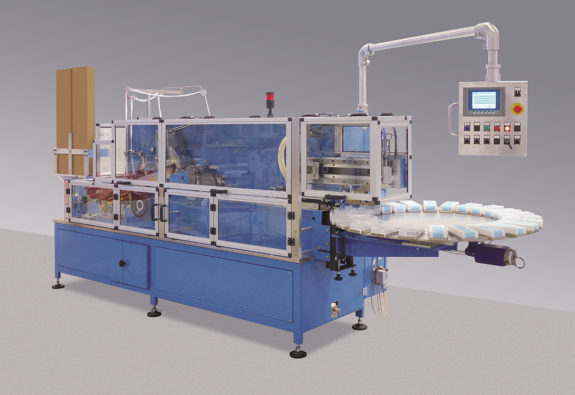

The Falu CB1 4.1 is a versatile cotton swab machine designed to be used in conjunction with the PRX stick machine. The CB1 4.1 production process has six segments starting with the feeding unit. Custom sticks made from materials such as plastic, wood, bamboo, paper, etc. are pushed through to the feeding unit. From there the sticks are separated and spaced accordingly for the adhesive section. Once they reach the adhesive section, they are either heated and molded, or glued in preparation for the cotton. After the stick is prepared, a small amount of cotton is tightly wound around the stick. The stick is then pushed through the molding unit where the bud is formed. The swab is then transferred to the drying station and once finalized, proceeds to the packaging machine/unit. The full encapsulation of the machine reduces noise and “cotton dust” in the environment.

Most process parameters can be controlled at the operation panel with an integrated touch-screen (for example: speed, the quantity of the starch/water mixture, cotton volume and other). Options like the integrated drying system, quality control unit or the precise hotmelt, helps to increase the overall efficiency of the line.

| Mechanical speed | up to 3’100 swabs per minute |

| Production speed | approx. 2’800 swabs per minute |

| Stick material | plastic, paper, wood |

| Cotton fixing with | heating, cold glue, hotmelt |

| Swab types | standard, safety (baby), cosmetic, medical |

| Packaging | semi-automatic with roundtable or fully automatic with automatic packaging machine |

| Additional options | industrial compact drying system quality control layer control cotton feeding drive |