No matter how well a machine is set up, there will be a few cotton swabs each shift with missing heads. For a very well-maintained machine with a fault occurrence rate as low as 0.02 %, this will result in around 200 packs per shift which contain a faulty swab. This leads to a lot of waste, which reduces productivity and revenue. With non-transparent packaging, this defect may go undetected, resulting in customer complaints and worse.

For the optimal efficiency of the production line, it is therefore required to remove all defective cotton swabs reliably before packaging. To take a big step forward in terms of reliability, we have upgraded our quality control to the latest proven state of the art using a camera-based approach.

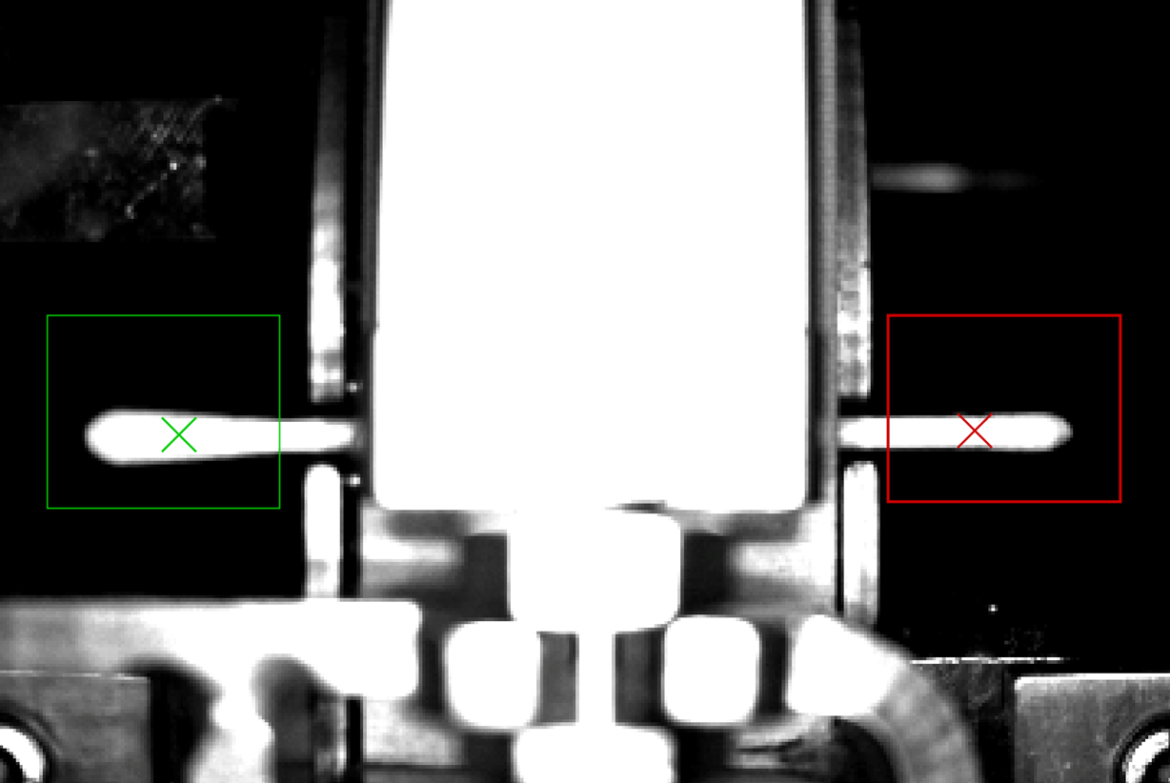

Our image-based high-speed inspection of swabs with a single evaluation device is setting a new standard in terms of robustness and reliability. Rather than using the fragile light guides fibre optics with no distance to the swabs, an industrial camera now evaluates the quality from a distance and ensures that defective swabs are ejected efficiently. If the machine ejects more swabs than usual, the easily accessible image memory facilitates the analysis of the problem by displaying photos of the defective swabs. The quality control based on a vision system is available for all FALU swab machines. It works with all swab types including baby and cosmetic products which so far could not be checked by our existing quality control.

Introduction of a waste reduction mode for the CB1

In many markets packages are allowed to contain less swabs than the declared quantity if – on average – the actual contents of packages is not less than the declared net quantity. In the latest version of the CB1 software it is possible to define the acceptable underfilling threshold. In this underfill tolerant mode the machine will reduce the waste generated by repicking and rejecting packages to a minimum and instead place an additional layer of swabs occasionally into the package to comply with the law in the most efficient manner for the most efficient use of resources